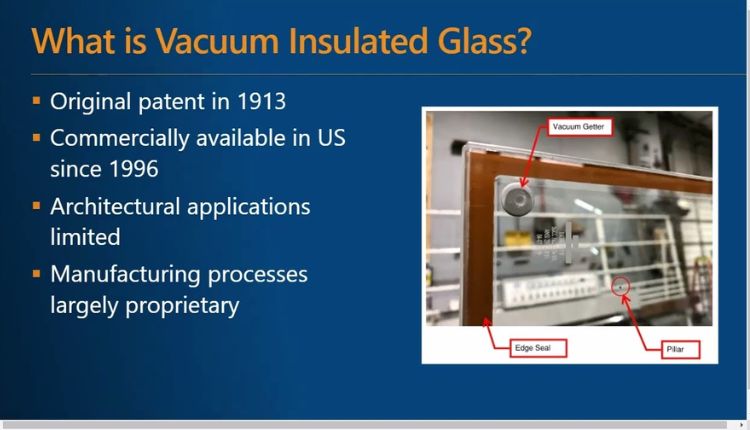

Heritage retrofits used to force a trade-off: keep the original window aesthetics or deliver modern performance. Vacuum insulating glass (VIG) dissolves that tension. By packing top-tier thermal and acoustic performance into a slim unit that often fits existing frames, VIG lets preservation teams protect character-defining features while delivering 21st-century comfort and efficiency.

Why heritage needs slim, high-performance glazing

Original sash and mullion profiles are sacred in conservation work. Thick triple glazing typically forces frame modifications that heritage authorities resist—and that can alter the façade’s rhythm and lightness. VIG provides low U-values in a cavity that’s comparable to double glazing, so you maintain slender sightlines, glazing bead proportions, and steel or timber frame authenticity.

Comfort, conservation, and condensation

Heritage structures frequently struggle with drafts, cold radiant surfaces, and condensation that damages woodwork. VIG elevates interior surface temperatures so occupants can sit close to windows without discomfort, and it lowers condensation risk—a win for preservation of finishes and indoor air quality. Over time, fewer repainting cycles and less wood repair can reduce maintenance costs.

Acoustic calm in urban contexts

Many historically significant buildings sit on busy streets. Noise intrusion undermines occupant experience in museums, hotels, and offices. Pair VIG with laminated lites to attenuate vibration and improve Rw/STC ratings. For a technical look at how vacuum cavities and laminates combine to enhance sound reduction, review this overview of hybrid VIG performance

From feasibility to approvals: a practical path

- Frame survey: Measure glazing rebate depth, check for warp or decay, and confirm tolerances. Thin VIG often fits where triple glazing cannot.

- Thermal modeling: Assess whole-window U-value and edge-of-glass temperatures to ensure condensation resistance. Include thermal bridge details at meeting rails and frames.

- Mock-ups and samples: Provide conservation officers with visual mock-ups and test data. A clear, layperson-friendly explainer helps, such as this resource demystifying vacuum glazing for sustainable buildings

- Installation strategy: Plan reversible interventions, compatible sealants, and glazing blocks. Ensure installers are briefed on handling and edge protection.

Evidence through precedent

Decision-makers are persuaded by case studies. This gallery of VIG projects spans climates, building ages, and uses—ideal for appendices in heritage applications and stakeholder decks: Reference VIG projects and case studies

Performance, durability, and maintenance

Quality VIG units use robust edge seals and getters to maintain vacuum for many years. Specify low-e durability, seal longevity testing, and warranties appropriate for conservation projects. In-service, expect warmer interiors, reduced HVAC loads, and a quieter acoustic environment—all accomplished while retaining original window character.

Embodied carbon and minimal intervention

Heritage practice prizes reversibility and minimal intervention. Because VIG can reuse existing frames in many cases, you avoid the embodied carbon and disruption of full frame replacement. The result: faster programs, lower waste, and retained heritage value.

Conclusion

Historic buildings deserve modern comfort and efficiency—without aesthetic compromise. VIG makes that feasible: slim, discreet, and high-performing. With proper surveying, modeling, and stakeholder education, it’s a conservation-friendly upgrade that honors the past while enabling a more sustainable future.